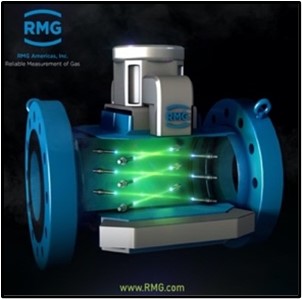

Tech Note 6 - GT 400 Upstream Piping Surface Roughness Test Results

By John Lansing, RMG Americas...

Traditionally gas ultrasonic meters are sent to a flow calibration facility with the upstream and downstream piping spools that will be installed in the field. Clients typically specify using a flow conditioner along with two upstream and one downstream spool. AGA Report No. 9 defines this combination of piping, flow conditioner and meter as a “metering package.” The reason for calibrating the USM with the specific spools and flow conditioner used for the field installation is ensure there is no bias that might arise by using different piping or flow conditioners. Shipping the complete metering package from the fabricator to the calibration facility and then on to the final destination can be costly. Typically, the complete metering package is also not disassembled after testing due to concerns this might affect the meter’s accuracy.

你有什么问题吗?

如果您有任何问题或需要帮助,请与我们联系。我们的员工永远都在你身边。

Phone +49 (0) 6033 897-0

info@rmg.com