Tech Note 3 - Shorter Upstream USM / CPA Piping Lengths Significantly Reduces Cost

By John Lansing, RMG Americas...

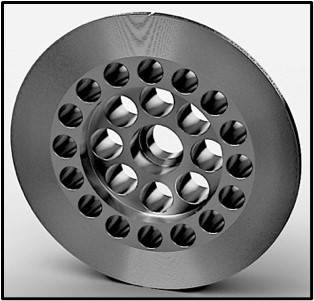

In North America Gas Ultrasonic Meters (USMs) have traditionally been installed with flow conditioning to reduce measurement uncertainty. Field upstream piping, that wasn’t included with the flow calibration, can increase overall uncertainty. A calibrated metering package usually consists of 10D + CPA 50E + 10D and the meter. There are thousands of USMs installed with this piping combination. As technology improved, clients (both Canadian and USA) are now asking for shorter upstream piping lengths to reduce facility costs. Measurement Canada (MC) requires meters be installed in accordance with their Document PS-G-06 [Ref. 1]. It details minimum piping lengths for use with the CPA 50E. In order to use piping shorter than their current 5D minimum, laboratory data is required to verify performance prior to approval. Recently Canada Pipeline Accessories (CPA) conducted testing at the TransCanada Calibration facility to obtain MC approval using an 8” RMG GT400 6-path USM and their newer CPA 55E (See Figure 1, Page 2) with 3D spools instead of the traditional 5D or 10D.

Estos son los componentes utilizados en los sistemas de RMG

Además de los instrumentos de medición y análisis, RMG le ofrece un software para una completa copia de seguridad y evaluación de los datos. Ya sea análisis de gas, revaluación o registro: Encontrará lo que busca con nosotros.

¿Tiene alguna pregunta?

Por favor, contáctenos si tiene alguna pregunta o necesita ayuda. Nuestros empleados siempre están ahí para ti.

Phone +49 (0) 6033 897-0

info@rmg.com