Turbine gas meter

Turbine gas meters are gas velocity meters and thus indirect volume measuring instruments. They are used for the exact determination of gas quantities. Typical applications are gas transport companies, storage facilities and in industrial high-pressure applications. If turbine meters are not subject to calibration, these counting instruments are often alternatively referred to as quantometers or volumeters.

Turbine gas meter

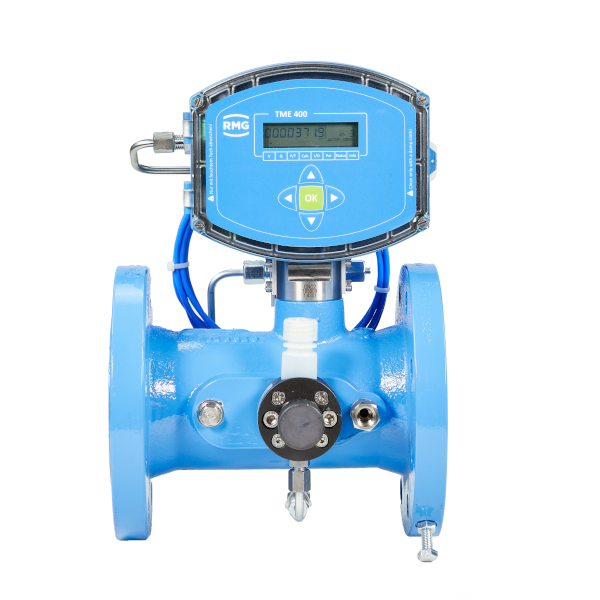

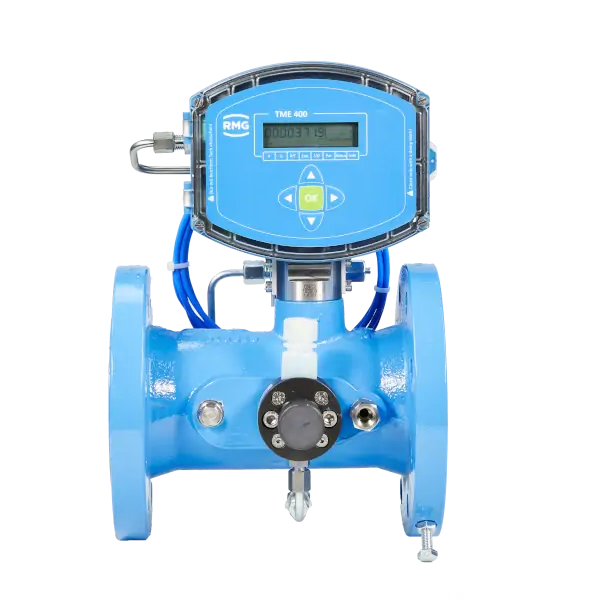

TME 400-VCF / TME 400-VMF

TME 400-VCF / TME 400-VMF

- TME400 -VCF with integrated volume corrector according to EN 12405-1

- TME400-VMF according to EN 12261 with electronic counter

- Special designs available for corrosive gases

Turbine gas meter

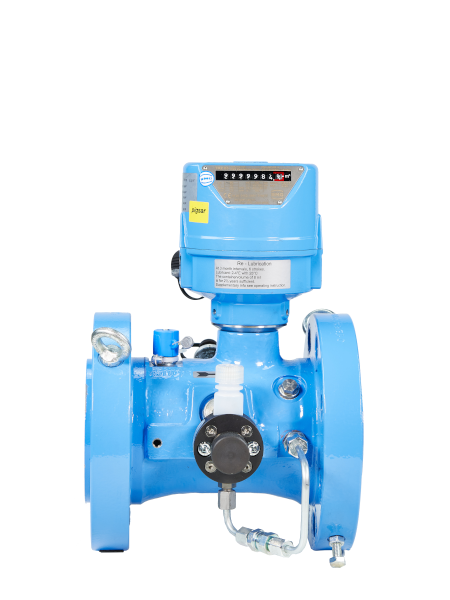

TRZ 03

TRZ 03

- Turbine meter TRZ 03 for custody transfer

- Suitable for neutral, non-aggressive gases, according to DVGW worksheet G 260

- Special turbine meter for aggressive gases possible

What are the essential components of a turbine meter?

Turbine gas meters consist of a pressure-bearing housing made of globular grey cast iron (GGG), cast steel or aluminium. The function-determining components inside the housing are the rectifier, the measuring unit with turbine wheel, the magnetic coupling, the pulse generator and the totalizer. The central unit of a turbine meter is the turbine wheel.

The measuring process is simplified as follows:

Gas flows through the inlet duct into the turbine meter. The flow straightener eliminates possible swirl in the gas flow. It equalizes and accelerates the gas flow by reducing the free cross-sectional area to a flow channel. In this flow channel the gas hits the freely rotating turbine wheel. The blades of the turbine wheel are at a precisely defined angle to the gas flow. The incoming gas drives the turbine wheel and sets it in rotation. As the flow rate increases, the speed of the turbine wheel increases. The speed of the wheel is proportional to the flow velocity (instantaneous value), the number of revolutions is proportional to the volume of gas flowing through (indirect volume measurement). Based on this law, the flow rate can be determined. The magnetic coupling transmits the speed of the turbine wheel via a gear to the mechanical totalizer.

Alternatively, special sensors can scan the turbine wheel without contact and the electrical pulses generated in this way can be transmitted to an electronic meter. This totals the quantity of gas flowing through in volume units and transfers the recorded data to a display.

Turbine meters are suitable for measuring the flow rate of various gases, e.g. natural gas, butane, propane, hydrogen, nitrogen, noble gases and others.

Depending on the intended use, turbine meters are available in different versions:

Turbine meters are also suitable for installation in pipelines with high pressure, since the magnetic coupling for transmitting the speed provides a perfectly sealing connection to the outside. The separate design of the measuring wheel and measuring device also allows the measurement of flammable and aggressive gases. A certain flow rate is necessary for a turbine meter to operate precisely.

The measuring process is simplified as follows:

Gas flows through the inlet duct into the turbine meter. The flow straightener eliminates possible swirl in the gas flow. It equalizes and accelerates the gas flow by reducing the free cross-sectional area to a flow channel. In this flow channel the gas hits the freely rotating turbine wheel. The blades of the turbine wheel are at a precisely defined angle to the gas flow. The incoming gas drives the turbine wheel and sets it in rotation. As the flow rate increases, the speed of the turbine wheel increases. The speed of the wheel is proportional to the flow velocity (instantaneous value), the number of revolutions is proportional to the volume of gas flowing through (indirect volume measurement). Based on this law, the flow rate can be determined. The magnetic coupling transmits the speed of the turbine wheel via a gear to the mechanical totalizer.

Alternatively, special sensors can scan the turbine wheel without contact and the electrical pulses generated in this way can be transmitted to an electronic meter. This totals the quantity of gas flowing through in volume units and transfers the recorded data to a display.

Turbine meters are suitable for measuring the flow rate of various gases, e.g. natural gas, butane, propane, hydrogen, nitrogen, noble gases and others.

Depending on the intended use, turbine meters are available in different versions:

- Turbine gas meters subject to calibration and non-custody transfer meters/volumeters

- Meters for low and high operating pressures

- Gas meter for measuring filtered and non-aggressive gases

- Turbine gas meters for corrosive, chemical and aggressive gases such as biogas, sour gas and ethylene. Such meters are made of special materials, are partly coated with Teflon and have a special lubrication

- Meters for use under extreme conditions, such as low temperatures

Turbine meters are also suitable for installation in pipelines with high pressure, since the magnetic coupling for transmitting the speed provides a perfectly sealing connection to the outside. The separate design of the measuring wheel and measuring device also allows the measurement of flammable and aggressive gases. A certain flow rate is necessary for a turbine meter to operate precisely.

Natural gas measurement with turbine meters

A typical example of the application of turbine meters is the measurement of natural gas quantities along the logistics chain. This supply chain has its origin in the gas production plant. The natural gas subsequently passes through several gas transport stations and finally reaches the local distribution and transfer stations. Turbine meters are used at every point in the supply chain to determine the exact quantities of gas. Further examples of the practical application of turbine meters are the use in power plants or for large industrial consumers (e.g. cement or glass industry), where exact gas measurement is also essential for billing and process control.

If you have any questions:

Turbine Gas Meter

Please contact us if you have any questions or need help. Our employees are always there for you.